How can electrical / mechanical scans help?

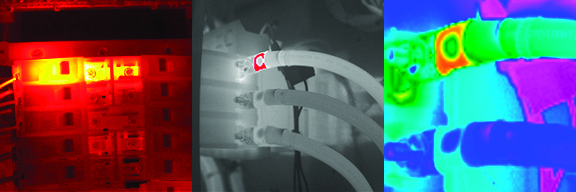

Infrared electrical inspections have become an integral part of any facility manager’s predictive/preventative maintenance program. Excess resistance on these components indicates a problem that could ultimately lead to component failure.

These infrared electrical inspections are used to prevent equipment damage and failure by detecting excess resistance (heat). Once an issue has been detected, maintenance personnel are able to correct it before component failure, which can lead to equipment damage, safety hazards, and even school closings.

What Electrical Distribution Equipment Should Be Checked?

- Utility substations, transformers and feed poles

- Main incoming services, main school disconnects, capacitor banks, etc

- Main switchboards and disconnects

- Main distribution panels and main disconnects

- Uninterruptible power supplies

- Generator controls and transfer switches

- Main I-Line panels

- Lighting and receptacle panels

- Disconnects and combination starters

- Service disconnects for motors

- Machine control panels

Interested in moisture detection surveys? Check out our infrared moisture surveys.

Why choose us?

- Unmatched experience within the application of aerial infrared

- Highest-quality infrared equipment available, capturing “invisible” problems

- Refined imagery collection and processing systems

- Professional & experienced staff of thermographers well-versed in infrared applications